PULSE VALVE

Pulse Valve FPV-01 is a non-contact valve that sprays grease to the area where it needs to be lubricated without touching workpieces. In order to achieve this function, a pneumatic high-speed solenoid valve is needed to control the opening and closing operation. The working frequency can reach up to 20hz. Thus fast, precise position and stable size of lubricating quantity can be achieved.

How to use?

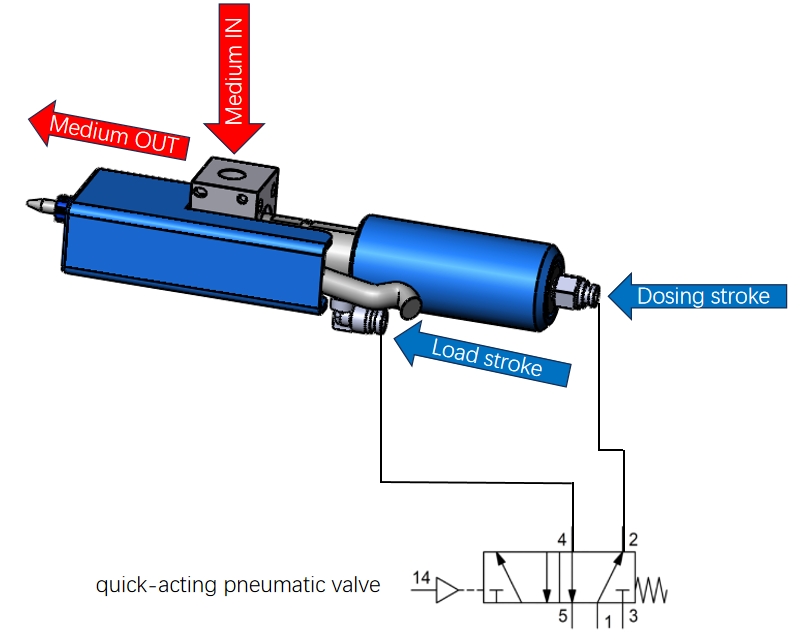

Control Circuit

Connection compressed air to “dosing stroke” -> Starting the dosing process;

Connection compressed air to “load stroke”-> load the valve for a new process;

Connection “Medium IN” to Pump / Material Supply;

Advantages

◆ Non-contact lubricant;

◆ Compact design can be integrated into many different lubricant system

◆ Accuracy dosing quantity

◆ Low medium pressure to avoid lubricant segregation

Technical data

Input medium specification NLGI 1-3

Medium pressure 0.5-12 bar

Working frequency 20 HZ

Dosing quantity 1-18 mm3/pulse

Inner diameter of nozzles 0.4/0.6/0.8/1.0/1.2/1.5

Air supply hose Ø ≥ 6 mm

Air pressure 4-7 bar

Air consumption 15 L/Min

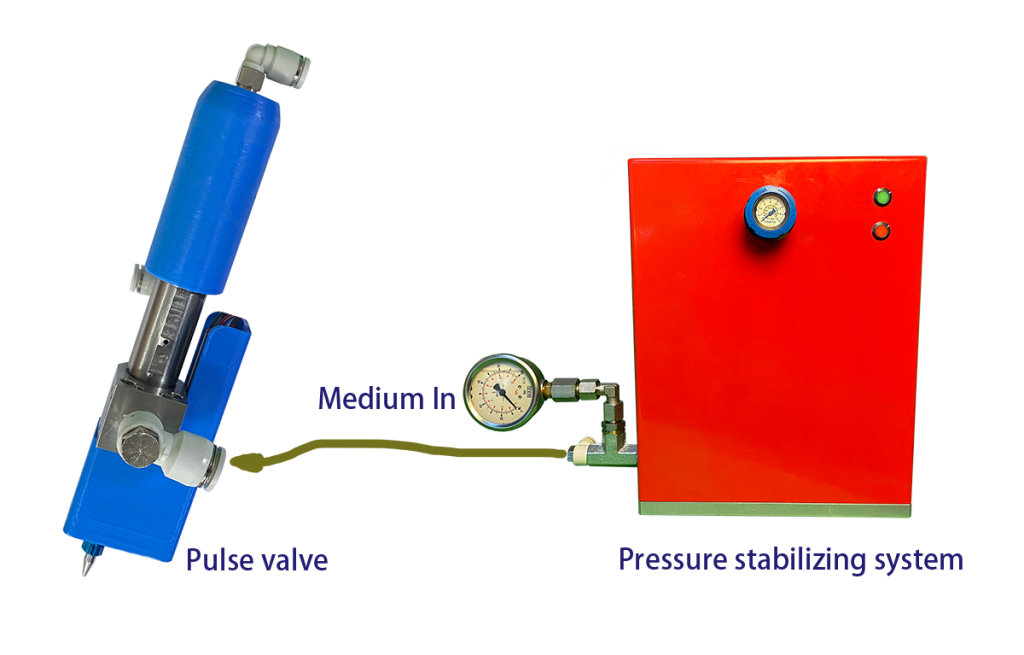

Pressure stabilizing system

The pressure stabilizing system is used to supply the PULSE VALVE with fluctuation free medium and the maximum output pressure is 12 bar max..

The function of the pressure stabilizing system is like bellow: Medium enters the compensation tank, in which a sensor and a pneumatic ball valve are integrated. Once the upper limit position is reached, the ball valve closes the supply. This process is repeated once the lower limit position has been reached. Because of the compensation tank, the output can be kept constant.

Power supply: 24 VDC Air pressure: 6-8 bar

Dosing medium:NLGI 1-3 Dimension (LXWXH): 375mmx125mmx290mm

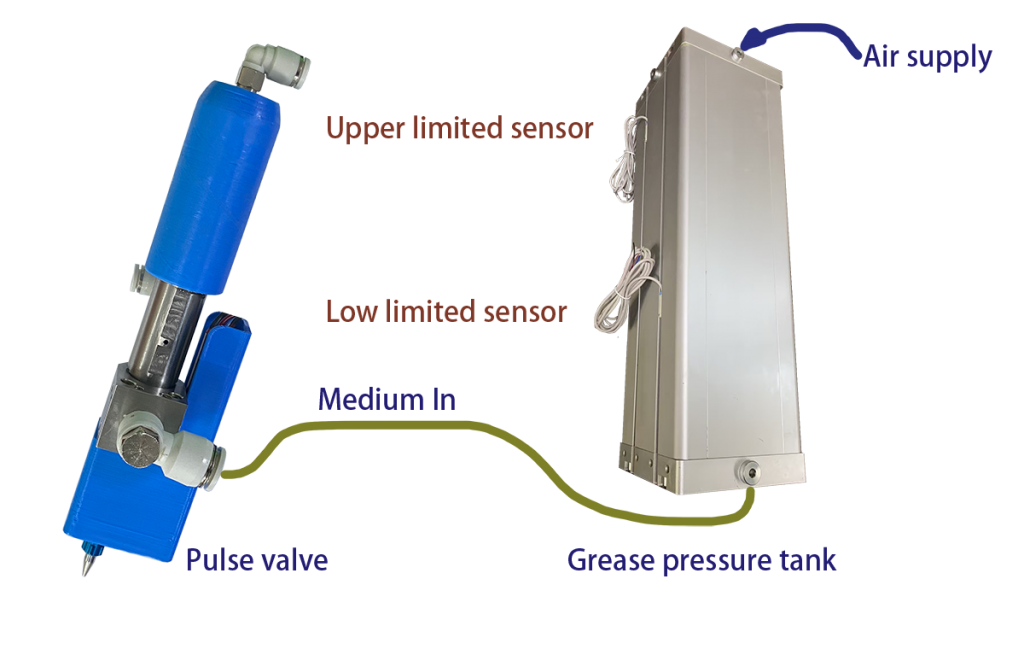

Grease pressure tank

Max. output pressure: 10 bar

Max. capacity: 3L

Max. air pressure: 10 bar