Rotary Dosing Unit

The Rotary Dosing Unit can be used to dispense greases and oils in different thicknesses onto cylindrical bodies. Different diameters can be processed without a changeover process. The use of a servo-axis enables sequential processing of the components in the axial direction.

Variable speeds are possible with a servo motor, which is Supported by integrated speed monitoring.The integrated dosing valve enables the dosing quantity to be adjusted with repeat accuracy during the dosing process and /or the travel path in the axial direction.

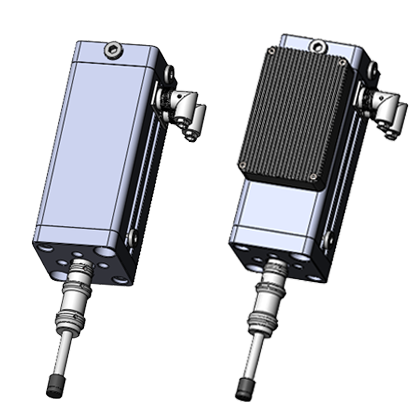

Both RDU01 and RDPU01 models are now available. RDU01 must work with RDU01-C. RDU01-C is responsible for controlling and monitoring the motor speed, while communicating with the upper controller, accepting the remote start and stop instructions of the upper controller, and transmitting the status information of the machine to the upper controller, such as waiting, rotation and error. RDPU01 integrates a motor driver, so in the case of providing DC 24 power supply, RDPU01 can be directly controlled by the customer’s own controller such as PLC and read the status information of the unit at the same time.

RDU01 AND RDPU01

Technical Data of RDU01

- Centrifugal plate diameter [mm] 10/ customized

- Lance length [mm] 100/150

- Speed [rpm] 6000-10000

- Operation medium Grease/ Oil NLGI class 0-3

- Max. working pressure medium inlet [bar] Depending on the material supply used

- Connection medium inlet internal thread G1/8

- Voltage [V AC] 230

- Min. /max. operation temperature [ °C ] 10/40

- Conveying capacity max. 1 cm3/s

- Volume <85 DB (A)

- MOTOR DATA

- Un 24V DC

- I N 3.5A

- P2 80W

Controller RDU01-C

A controller RDU01-C is required to drive the execution unit RDU01 . So the connection plan between them likes bellow.

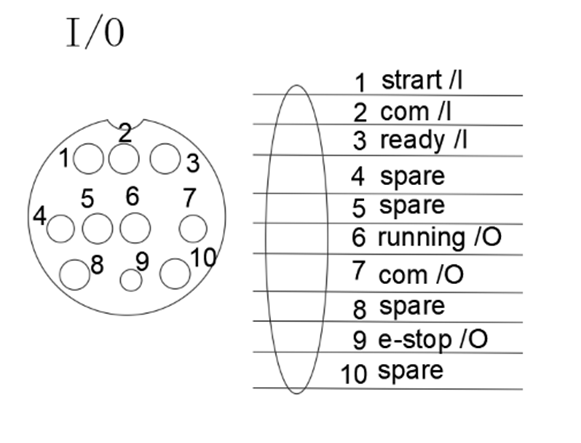

I/O PIN definition & control sequence

I/O definition

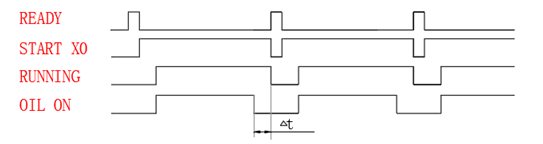

control sequence

NOTE: Grease /oil must be cut-off before the motor stops. The amount of lead time Δt depends on the parameters such as flow rate or viscosity of the oil/ grease or some others.

Dimension of RDU01

Technical Data of RDPU01

Function unit RDPU01 can work independently. The upper controller can start and stop RDOU01 directly by I/O signal . In addition, the rate of RDPU01 can be set and read in real time through the RS485 interface

- Centrifugal plate diameter [mm] 10/ customized

- Lance length [mm] 100/150

- Speed [rpm] 6000-10000

- Operation medium Grease/ Oil NLGI class 0-3

- Max. working pressure medium inlet [bar] Depending on the material supply used

- Connection medium inlet internal thread G1/8

- Frequency [Hz] 50

- Voltage [V DC] 24

- Min. /max. operation temperature [ °C ] 10/40

- Conveying capacity max. 1 cm3/s

- Volume <85 DB (A)

- MOTOR DATA

- Un 24V DC

- I N 3.5A

- P2 80W